Weichai Group Launches the World's First Commercialized Diesel Engine with a Brake Thermal Efficiency Over 50%

2020-09-16

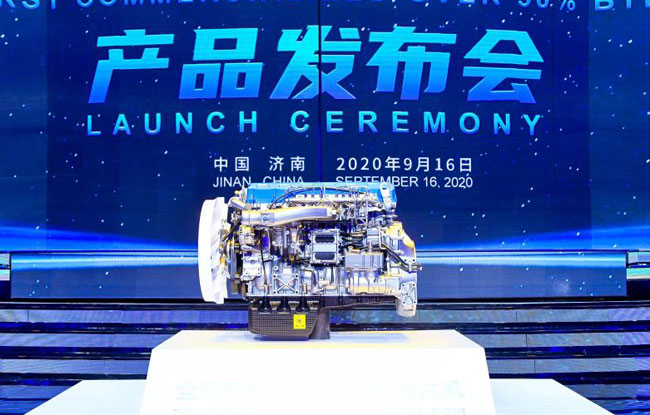

On September 16, 2020, Weichai Group, a leader in China's internal combustion engine industry, held a launch ceremony in Jinan, Shandong, China, officially launching the world's first commercialized diesel engine with a brake thermal efficiency over 50%.

At the ceremony, world authoritative testing organization TÜV SÜD, and China’s national internal combustion engine testing organization China Automotive Technology and Research Center Co., Ltd. both awarded Weichai test report for brake thermal efficiency of 50.26%. Ling Wen, vice governor of Shandong Province and academician of the Chinese Academy of Engineering, and Tan Xuguang, chairman of Shandong Heavy Industry Group and Weichai Group, jointly unveiled the world's first commercialized diesel engine with a brake thermal efficiency over 50%.

Brake thermal efficiency is a measure of the fuel efficiency of internal combustion engines. The higher the brake thermal efficiency is, the less the fuel consumption will be and the better the energy saving and emission reduction performance will be. Since the world's first diesel engine was successfully developed in 1897, after a hundred years of transformation and upgrading and new technology application, the brake thermal efficiency of the diesel engine increased from 26% to 46% until now. From the statistics of the development of the brake thermal efficiency of diesel engines in the world, with the increasingly stringent emission regulations, the improvement of brake thermal efficiency has encountered a big bottleneck. The improvement is becoming more difficult, and the progress is slow. This is a world-recognized technical problem in the industry.

Weichai has been deeply involved in the internal combustion engine industry for more than 70 years, and has deep technical background and accumulated experience in the manufacturing and development of diesel engines by continuously researching key and core technologies. Weichai has invested 30 billion yuan in R&D over 10 years and recuited more than 200 doctors, more than 300 global high-end talents and more than 3,000 graduate students. Weichai has achieved a leap-forward development of independent innovation in the diesel engine industry, and estblished the world’s only R&D and production base with annual manufacturing and sales of more than 1 million units in Weifang, and promoted breakthroughs in the core technologies of commercial vehicle powertrains, CVT powertrains, and hydraulic powertrains, complementing China's core technical shortcomings in these three areas and promoting China's diesel engine industry chain to continue to move towards the high end.

In recent years, Weichai has gathered superior resources to carry out special research on brake thermal efficiency improvement. Especially since 2015, Weichai has established a special technical research team to use a large number of simulations and bench tests for thousands of solutions attempts and improvements. Every arduous cumulative progress of 0.1% finally led to a historic breakthrough. Weichai created five proprietary technologies: advanced fields synergy combustion technology, harmonius design technology, exhaust energy distribution technology, subzone lubrication technology and WISE control technology, which all help solve a series of world-class problems and achieve high efficiency combustion with low heat transfer, high PFP with high reliability, low friction loss, low emission pollutants, intelligent control, etc., so that the brake thermal efficiency of the base diesel engine exceeds 50%.

Among these technologies, the advanced fields synergy combustion technology optimizes the design of the air passage, fuel injection, combustion chamber profile and other systems to make the relationship between the velocity field and concentration field in the combustion chamber more harmonious, and the combustion speed increases by 30%.

The harmonius design technology, in view of the difficult problem that the diesel engine body's ability to withstand the high PFP greatly limits combustion improvement, selectively weakens some parts in order to finally strengthen the overall structure, and increases the system's PFP withstand capacity by about 60%.

Exhaust energy distribution technology, in response to the increased difficulty of pollutant emission control caused by improved combustion, pioneered reconstruction of the exhaust system design. It adapts to the demand for exhaust gas recirculation, while ensuring the efficiency of turbines, meeting the requirements of regulations and standards and achieving a 1% increase in brake thermal efficiency at the same time.

Subzone lubrication technology is developed based on the different characteristics of the friction pairs of the system, and uses different friction reduction technologies in different areas to reduce the overall friction by 20%.

WISE control technology, using the advantages of Weichai's self-developed ECU, creatively develops a series of more precise control predictive models, so that every part of the diesel engine can be more efficient.

The brake thermal efficiency exceeding 50% is a historic revolution in the development of internal combustion engines in the world. Authoritative institutions and experts at home and abroad, such as Bosch Group, AVL List GmbH, FEV, SAE, China Machinery Industry Federation, China Internal Combustion Engine Industry Association, and China-SAE, respectively congratulated Weichai on this historic breakthrough and praised Weichai for setting a new benchmark for the brake thermal efficiency of global diesel engines and making new contributions to the energy saving and emission reduction of internal combustion engines.

Weichai not only launched the first base diesel engine with a brake thermal efficiency of over 50% to the world, but also easily met the China VI/Euro VI emission requirements, and was the first one ready for mass production and commercialization. Industry experts pointed out that based on the current 46% industry brake thermal efficiency level, when it increases to 50%, the diesel consumption will be reduced by 8%, and carbon dioxide emissions will be reduced by 8%. According to the current estimate of the current number of 7 million units in China’s heavy-duty diesel engine market, if all are replaced with diesel engines with 50% brake thermal efficiency, we can save 33.32 million tons of fuel and reduce carbon dioxide emissions by 104.95 million tons per year. This will make a significant contribution to solving energy shortages and global warming problems.

The launch of the world's first commercialized diesel engine with a brake thermal efficiency of over 50% marks that China's heavy-duty diesel engine technology has advanced to the world's top. Weichai has received strong support from Bosch Group, and other global suppliers and R&D consulting institutions in the development of this program. At the ceremony, Tan Xuguang announced that in the future Weichai will link up with global partners more openly and move towards the goal of 55% brake thermal efficiency for diesel engines!