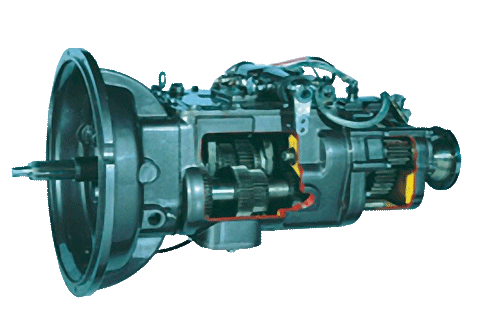

Structure Characteristics

- Both main and auxiliary cases equipped with twin countershafts, power well distributed, high reliability

- Small center distance (105mm ), small volume and light weight.

- The main shaft and gears are floating, there are no needle bearings between shaft and gears, high efficiency in power transfer

- With thin-and-fine teeth gear design (contact ratio ε >2), stable engagement and low noise.

- Fully synchronized: both main and auxiliary cases are equipped with double taper faced synchronizers of lock-ring model, large synchro-capacity, and easy and flexible shifting.

- Combined design of main and auxiliary cases, small ratio steps and good fuel efficiency.

- There are many types of power taking off, catering to various power output demands of refitted trucks.

- Single H, double H, single-lever or double-lever operating mechanism can be realized.

Technical Parameter

| Models |

Torque(N·m) |

Gear Ratios |

Weight (Kg) |

oiling (L) |

| 1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

RL |

RH |

| 8JS75T |

750 |

8.12 |

6.08 |

4.47 |

3.31 |

2.46 |

1.84 |

1.35 |

1.00 |

8.12 |

2.46 |

186 |

9 |

| 8JS85T |

850 |

8.12 |

6.08 |

4.47 |

3.31 |

2.46 |

1.84 |

1.35 |

1.00 |

8.12 |

2.46 |

186 |

9 |

| 8JS95T |

950 |

8.12 |

6.08 |

4.47 |

3.31 |

2.46 |

1.84 |

1.35 |

1.00 |

8.12 |

2.46 |

186 |

9 |

| 8JS115T |

1150 |

8.12 |

6.08 |

4.47 |

3.31 |

2.46 |

1.84 |

1.35 |

1.00 |

8.12 |

2.46 |

186 |

9 |

| 8JS75TA |

750 |

6.01 |

4.50 |

3.31 |

2.45 |

1.82 |

1.36 |

1.00 |

0.74 |

6.01 |

1.82 |

186 |

9 |

| 8JS85TA |

850 |

6.01 |

4.50 |

3.31 |

2.45 |

1.82 |

1.36 |

1.00 |

0.74 |

6.01 |

1.82 |

186 |

9 |

| 8JS95TA |

950 |

6.01 |

4.50 |

3.31 |

2.45 |

1.82 |

1.36 |

1.00 |

0.74 |

6.01 |

1.82 |

186 |

9 |

| 8JS115TA |

1150 |

6.01 |

4.50 |

3.31 |

2.45 |

1.82 |

1.36 |

1.00 |

0.74 |

6.01 |

1.82 |

186 |

9 |