-

Company

-

Product

-

Support

-

Investors

-

Sustainability

-

Careers

-

Media

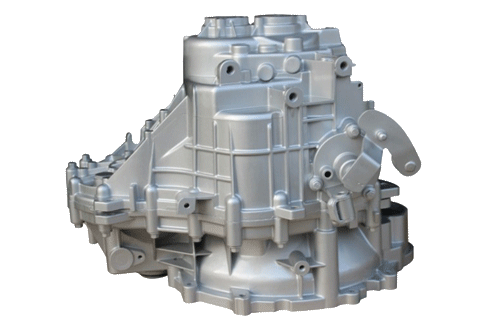

| Model | ZQC5T15C Series | ||||||

| Basic Structure | Front-engine front-drive, 2-shaft design, synchronization for all forward speed shift, all transmission ,main reducer and differential as a whole. |

||||||

| Main Ratio | 4.053/3.667/4.353 | ||||||

| Speed/Ratio | Ⅰ | Ⅱ | Ⅲ | Ⅳ | Ⅴ | R | Remark |

| 3.308 | 1.913 | 1.226 | 0.889 | 0.718 | 3.231 | 15C1-E | |

| 3.667 | 1.913 | 1.188 | 0.889 | 0.718 | 3.231 | 15C1-D | |

| 3.308 | 1.913 | 1.258 | 0.943 | 0.763 | 3.231 | 15C1 | |

| Center Distance | 68 /115 mm | ||||||

| Max Input Torque | 150 N·m | ||||||

| Shifting Mechanism | Double rod control | ||||||

| Lubricant Oil | 2.2L/GL-4 | ||||||

| Weight(kg) | 33 kg | ||||||

| Engine Type/Car Model | 4A9 | ||||||

| L×W×H(mm) | 364×488×420 /mm | ||||||

| Description | 1. All Aluminum alloy housings are die cast of aluminum alloy for lightweight. 2. Slider type synchronizers are used for all forward speed shift, and three cone synchronous ring is used for the 1st and the 2nd shift with large capacity, and smooth, flexible and reliable shifting is realized, while leverage synchronizer is used for reverse shift and makes the reverse shifting smoothly. 3. Optimized design and strengthen process have for all gears made the gearbox feature with high torque capacity and quiet noise level. 4. The reverse shift adopts the sliding shift and shifting lock mechanism, which to avoid the 5th shift straying into the reverse shift position when shifting, thus improve the safety and reliability of the car; 5. Fork shaft positioning makes the clear, smooth feel 6. Can be matched with a variety of engine between 1.1-1.5L |

||||||